What is Six-Side Continuous Anodizing

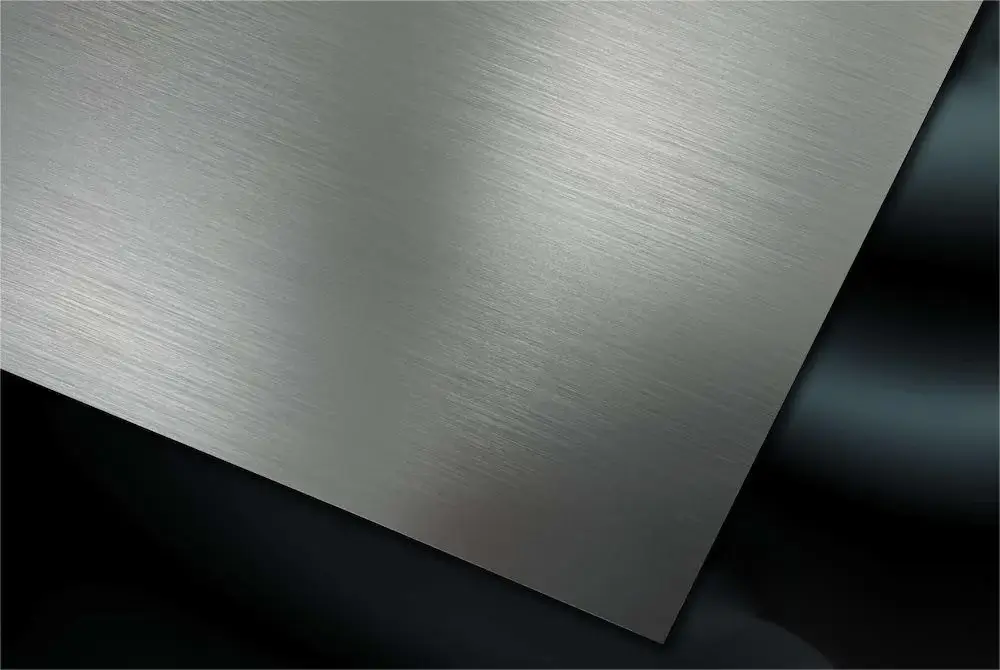

Six-Side Continuous Anodizing is a cutting-edge technique that ensures that all six sides of an aluminum sheet, including the front, back, and the four cut surfaces, are anodized using a continuous sheet anodizing process. This method successfully address the problems of color difference and achieving anodization on all six sides.

Benefits of Six-Side Continuous Anodizing

1.Consistent Color: One of the most significant advantages of Six-Side Continuous Anodizing is the ability to achieve a consistent color across all six sides of the aluminum sheet. This ensures that your project maintains its aesthetic appeal and quality.

2.Enhanced Durability: Anodized aluminum is known for its exceptional durability and resistance to corrosion. By anodizing all six sides continuously, the protection extends to every surface, providing long-lasting performance in even the harshest environments.

3.Versatility: This advanced anodizing method is applicable to a wide range of aluminum products, including architectural cladding, automotive components, consumer electronics, and more. It opens up new possibilities for design and application.

4.Cost Efficiency: Six-Side Continuous Anodizing reduces the need for rework and increases efficiency in production. This can lead to cost savings for manufacturers and a more competitive final product.

Applications of Six-Side Continuous Anodizing

1.Architectural Cladding: Six-Side Continuous Anodizing is a game-changer for architects and designers looking to create stunning, long-lasting building facades. The uniform finish ensures a consistent appearance, even at the edges of panels.

2.Automotive Components: Anodized aluminum is frequently used in automotive components for its lightweight, corrosion-resistant properties. Six-Side Continuous Anodizing is ideal for these applications, ensuring that every surface is protected.

3.Consumer Electronics: From sleek smartphone casings to laptop bodies, Six-Side Continuous Anodizing offers the precision and uniformity required in the electronics industry. It enhances product aesthetics while maintaining durability.

4.Marine Equipment: The marine industry relies on materials that can withstand the harsh conditions of saltwater environments. Six-Side Continuous Anodizing provides the necessary corrosion resistance for marine equipment and structures.

Six-Side Continuous Anodizing is revolutionizing the aluminum industry, addressing the challenges of inconsistent color and incomplete anodization. This advanced technique provides numerous benefits, including a uniform finish, enhanced durability, versatility, and cost efficiency. Its applications are diverse, ranging from architectural cladding to consumer electronics and more. By choosing Six-Side Continuous Anodizing, manufacturers and designers can ensure their aluminum projects meet the highest standards of quality and aesthetics.

Contact us, embrace this innovative solution to elevate your aluminum products to perfection!