Why anodized film ‘crazing’ when anodized aluminum sheets are bent?

The root cause of ‘crazing’ in anodic oxide film is: aluminum anodic oxide film is brittle, while the coefficient of linear expansion is 1/5 of the aluminum substrate, and this large difference in the coefficient of linear expansion affects its thermal deformation and mechanical deformation properties, resulting in crazing.

Is there a solution that can not only meet the aesthetic requirements of design, but also solve the problem of anodized film crazing?

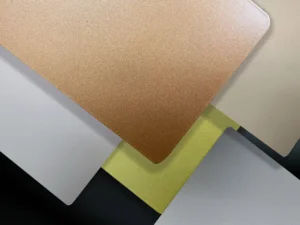

Yes, there is! To address the issue of color difference and crazing in anodized film, Altal has successfully developed a new generation product: Colored Anodized Plated Aluminum Sheet for exterior use.

The new product utilizes anodized coating technology. This involves applying ion deposition plating after anodizing for the purpose of coloring and sealing, replacing the traditional method of anodized electrolysis and sealing. This new technology can solve not only the crazing issue of anodized film but also the problem of color difference. Another perfect property of anodized plated aluminum sheet is its aesthetic appearance. It is rich in color, and the control of color difference is excellent, ensuring the consistent appearance of each aluminum sheet. At the same time, the optimization of the surface treatment process makes the aluminum sheet surface more delicate, which meets the design requirements, and also satisfies the pursuit of aesthetic.

Effectively solve the problem of color difference and film crazing

Effectively solve the problem of color difference and film crazing, the anodized plated aluminum sheet subverts the traditional processing technology of aluminum veneer. For the traditional manufacturing process of aluminum veneer, it needs sheet metal processing first, and then sent to the surface treatment factory for subsequent processing. It is costly and inefficient.

Using the new generation product – Anodized Plated Aluminum Sheet, you do not need to worry about this. By utilizing this process technology, it does not need outward processing, only need to complete the sheet metal processing in the factory, and then can be packaged and delivered. Elimination of intermediate handling and logistics links, greatly reducing logistics losses and surface treatment waiting time. This undoubtedly greatly improves productivity and reduces production costs.

The innovation of outdoor used colored anodized plated aluminum sheet, successfully solves the color difference and film crazing problem of traditional anodized aluminum sheet, while brings stronger weather resistance, corrosion resistance, and beautiful appearance, as well as better processing performance. Such products will undoubtedly bring great value and potential to the construction industry and become the new trend of building exterior decoration in the future.